SPECS OVERVIEW

- Cooling capacity range between 91 – 722 kW

- Choice of single (G) or dual (L) circuits

- Using Daikin Scroll Compressor

- SEER and EER up to 5.55 and 4.60 respectively.

- Compact design with highest KW/m2 ratio & quiet operation

- R-410A Refrigerant

BENEFITS

- Low sound configuration with optional acoustic enclosure (Average reduction 6dB (A))

- Wide range of cooling capacity with one or two refrigerant circuit

- Hydronic Kit featuring Low and High lift static pressure (100 and 200 kPa respectively)

- Partial heat recovery using plate to plate heat exchanger for sanitary hot water production

FEATURES

- Compact design with modular conception that allows unit stacking reaching largest KW/m2 ratio on the market

- Wide capacity range with the introduction for the new 60 HP scroll compressor

- The MicroTech III controller with superior control logic and compatibility with LonWorks, BACnet, Ethernet TCP/IP or Modbus RTU communications; App ready and Daikin cloud monitoring platform connectivity – Daikin on Site

- Stainless steel brazed plate to plate heat exchanger Evaporator and Condenser with optional factory mounted Victaulic kit and flowswitch

- Heat pump version features a reversing cycle on water side

Certified in accordance with the Eurovent Certification Program.

Certified units may be found in the Eurovent website at www.eurovent-certification.com

Get Quotation

Get in touch with details about the requirements of you project, indicating operating conditions, plus options, controls you are interested in, and any other relevant information. This will allow us to get back to you in no time with the best offer for your needs.

References

Daikin has provided value with its cutting-edge and sustainable technology helping to comply with the efficiency standards required (EN 1235/14), for both heat recovery and overall AHU power. Use of the latest high efficiency EC motor, low pressure drop and low maintenance components were the key features of the proposal by Daikin Applied. This was adopted by the Skanska design team as it exceeded the clients expectations in unit size, performance, efficiency and budget.

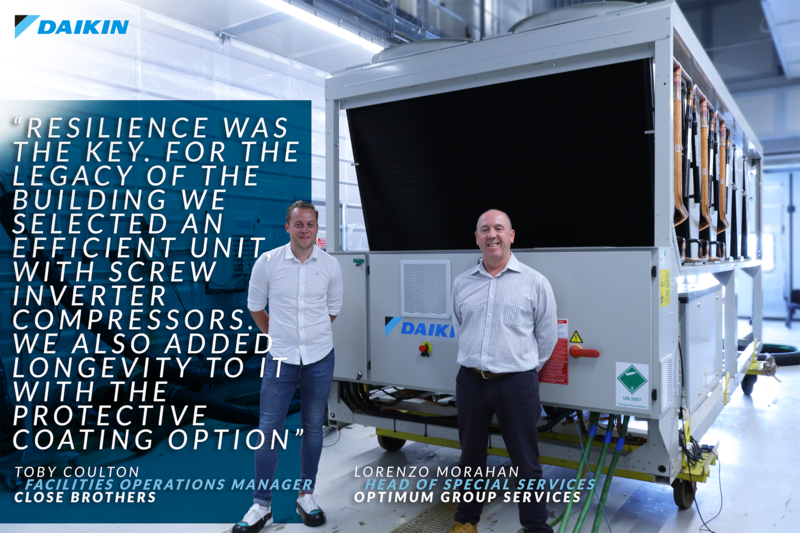

We met Lorenzo Morahan, Head of Special Services and Energy at Optimum Group Services, and Toby Coulton, Facility Operation Manager at Close Brothers, both working on the #replacement of a chiller in a Close Brothers building in London.

The industry is braced for a series of key legislative changes: New Building Regulations Parts F, L and O, Building Safety Act and MEES. Follow the link for more details on what you need to know.

Chillers and heat pumps built at Daikin Applied’s factory in Italy are being charged with reclaimed R-134a as part of the company’s strategy to reduce environmental impact and develop a ‘circular economy’ of refrigerants, reclaiming up to 400,000 kg/year of R-134a.

The data centre market is already vast and its growth keeps accelerating. The question for building services engineers is how to keep up with the industry’s voracious appetite for cooling, ventilation and power without doing further harm to the environment. Daikin Applied’s Amin Dadgari has some answers.

Here’s what Francesco Aruta, IT Systems Director overseeing the DoS projects told us: Daikin on Site springs from the desire to offer a constantly evolving service to our clients. It’s an innovative remote monitoring tool for Chiller plants and Air Handling Units, providing information with a unique level of detail. DoS allows to take preventive actions, so plant owners can avoid extra costs associated with breakdowns.